|

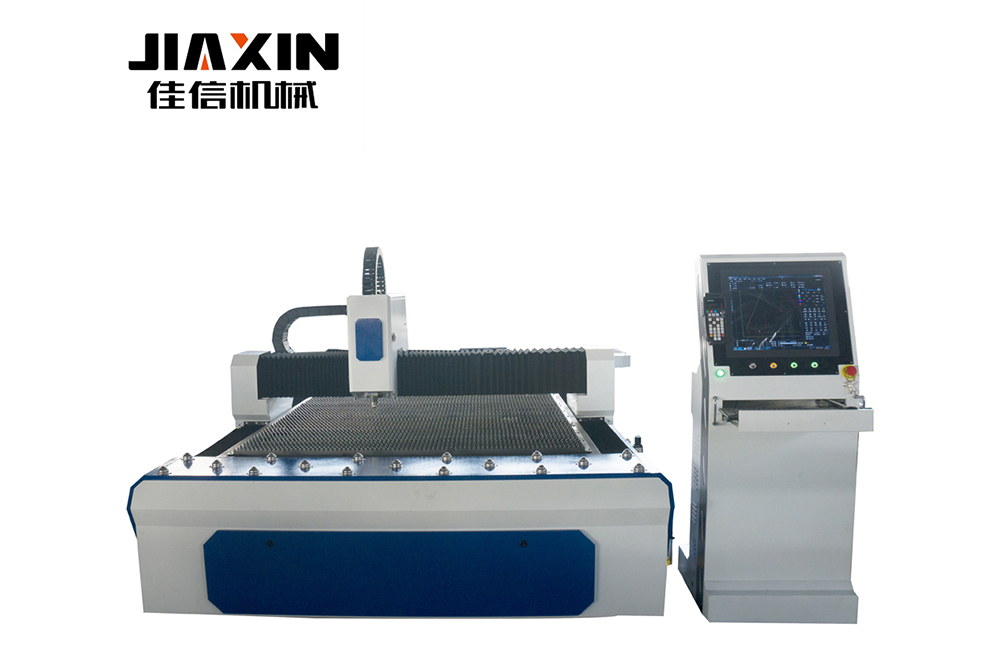

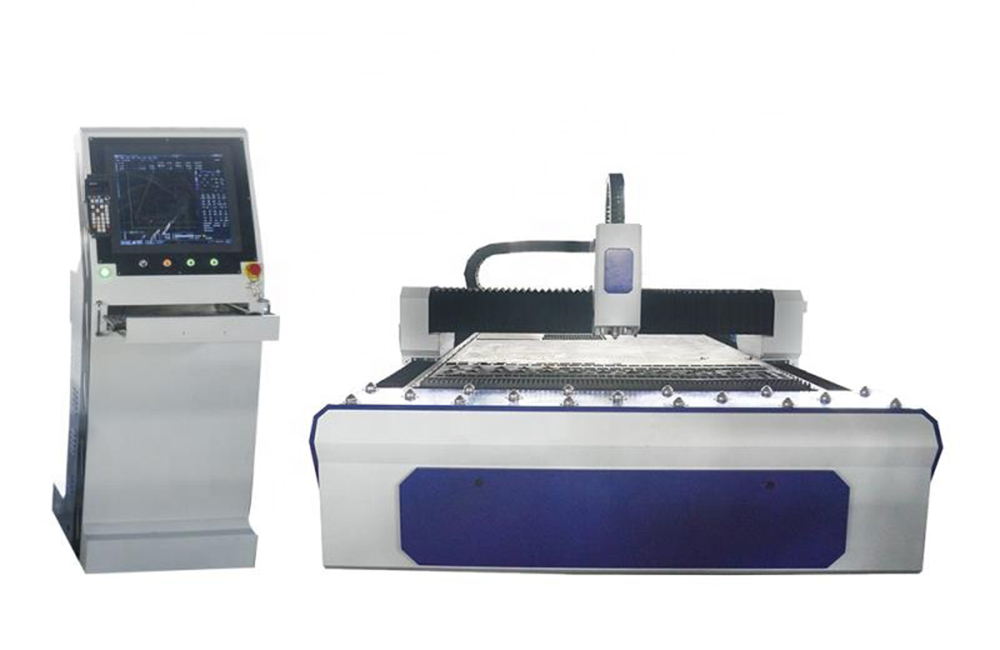

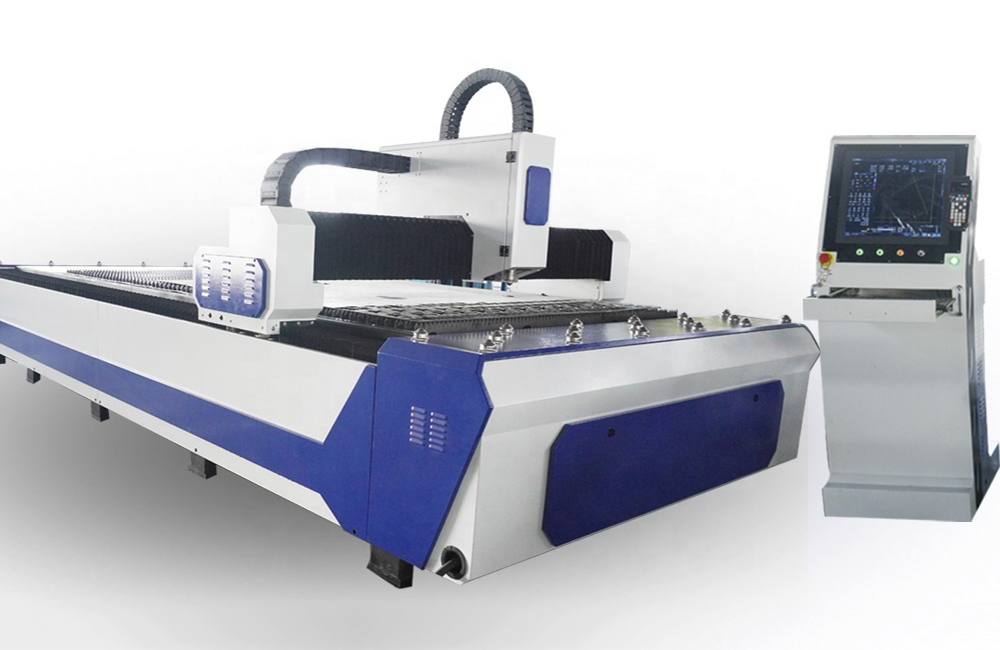

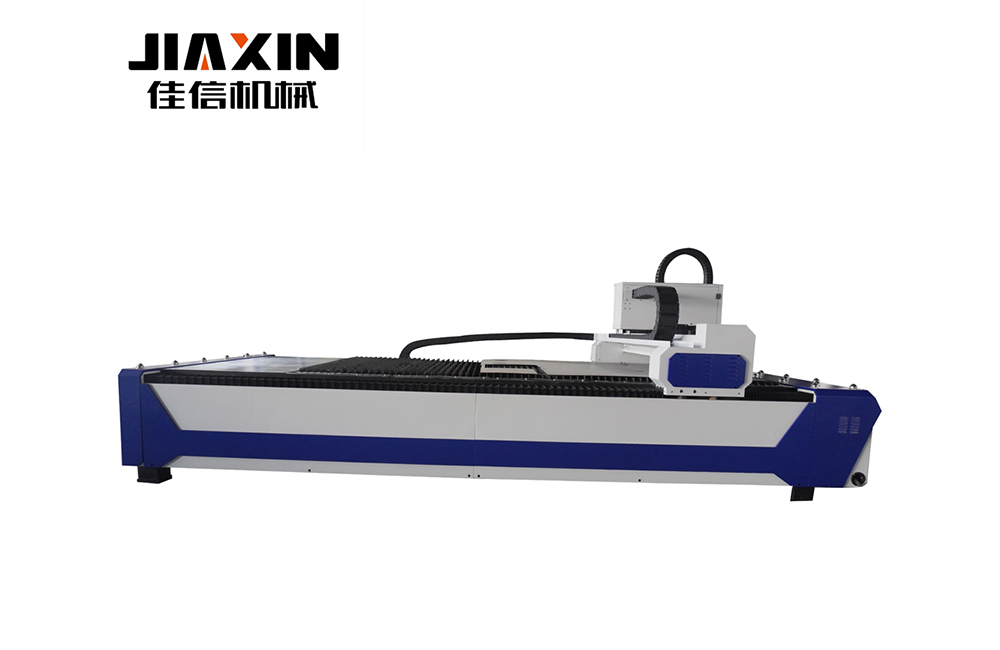

JX3015-3000W Fiber laser cutting machine |

|

|

Mainframe structure |

Double drive gantry structure |

|

Working table width |

1525 mm |

|

Working table length |

3050 mm |

|

Cutting steel plate thickness |

Carbon steel≤20mm,Stainless steel≤10mm |

|

X, Y axis drive mode |

Imported precision rack and pinion (helical) |

|

X-axis effective cutting range |

1525 mm |

|

Y-axis effective cutting range |

3050 mm |

|

X/Y axis maximum linkage positioning speed |

100m/min |

|

X, Y axis maximum acceleration |

1.1G |

|

Power parameter |

|

|

Phase No. |

3 |

|

Power supply rated voltage |

380V |

|

Frequency |

50Hz |

|

Total power protection level |

IP54 |

|

Weight and size |

|

|

Worktable maximum load |

4000kg |

|

Machine weight |

5000Kg |

|

Dimension(length×width×height) |

4880mm×2260mm×1600mm |

Product Advantage

-

Professional laser optical system and imported lenses, stable and reliable

Efficient and stable programming and control system, easy to learn and humanized, compatible with a variety of CAD drawing formats, intelligent nesting to save costs, automatic cutting path (a set of automatic nesting software) matching saves processing time

The product has low energy consumption and low cost of use; high equipment stability, simple and convenient maintenance, and low maintenance cost

No mold required, flexible processing, can meet the processing requirements of various special-shaped workpieces

High cutting efficiency, high cutting quality, no noise; high speed, high efficiency, cutting sheet speed up to several 30 meters per minute; cutting edge quality, small deformation, smooth and beautiful appearance;

High-precision servo motors, guide rails, gears and racks made in Taiwan, while ensuring processing efficiency and processing accuracy, greatly improving the stability and reliability of equipment operation

Applicable Materials and Industry Applications

-

Application industries: metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agricultural and forestry machinery, elevator manufacturing, special automobiles, household appliances manufacturing, tool processing, IT manufacturing, petroleum machinery manufacturing, food machinery , Diamond tool welding, gear welding, metal material surface treatment, decorative advertising, laser external processing services and other machinery manufacturing and processing industries.

Applicable materials: professionally used to cut a variety of medium and thin metal plates, high-quality cutting 0.5-10mm carbon steel plates, and can also cut stainless steel plates, aluminum alloy plates, galvanized plates, electrolytic plates, silicon steel, titanium alloys, aluminum-zinc plates, etc. Kind of metal material.