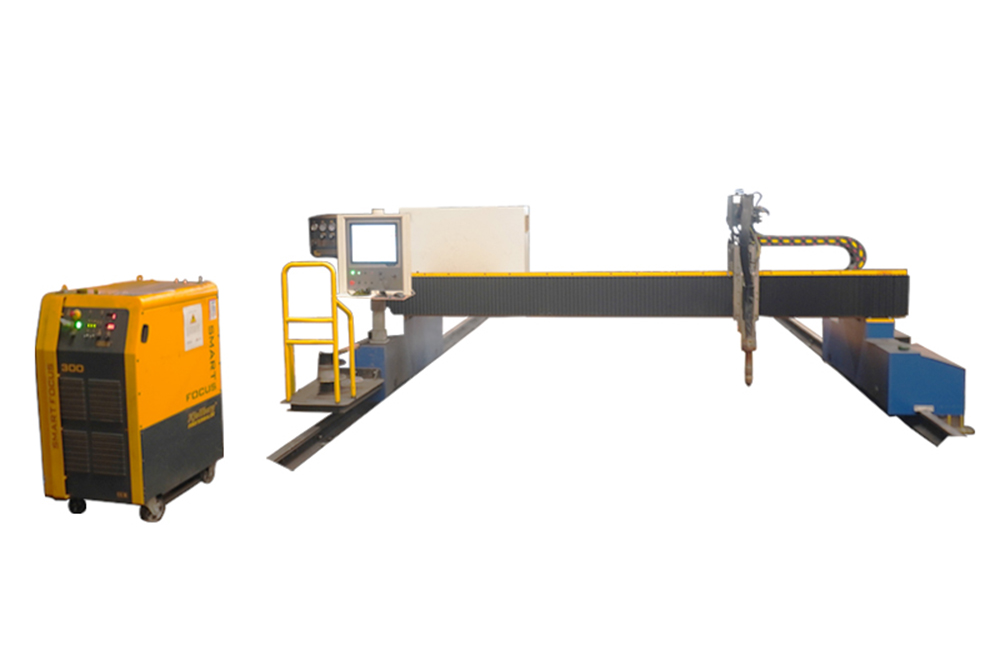

Fine Gantry CNC Plasma and Flame Cutting Machine

-

Product description:JX series CNC precision plasma cutting machine is a kind of high-efficiency steel plate automatic cutting and blanking equipment developed by our company after absorbing advanced software and hardware technology at home and abroad for supporting metal structure processing. It can cut longitudinally and horizontally, and the arc curve also can be cut in any direction, with high cutting surface roughness and precision and small deformation. The machine has the advantages of reasonable structure, simple operation and advanced technology. The components of JX-F series cutting machine include numerical control system, drive system, control system, mechanical system and pneumatic system. Laser-like CNC systems and servo systems use well-known brands at home and abroad, excellent performance products, convenient human-machine interface, friendly operation, rich software and high-quality hardware configuration, and comprehensive protection measures to provide users with a high-quality product.